An 1842 day at “Day and Martin’s”

An eight page article published in “The Penny Magazine” Volume XI, December 1842, published by “The Office of the Society for the Diffusion of Useful Knowledge”.

An eight page article published in “The Penny Magazine” Volume XI, December 1842, published by “The Office of the Society for the Diffusion of Useful Knowledge”.The author is unnamed but his verbosity knows no bounds. Still, it give a great insight into the busy and well organised business of boot blacking, a major concern of it’s day. Rather irritatingly detail where we would like it is missing, particularly the composition and processing of the blacking (although later described William Charles Day, and seems to be very similar to what contemporary manufacturers were doing) and I would have been interested to read about the office staff as well as the factory staff. The engravings are fantastic though.

THE PENNY MAGAZINE

A DAY AT DAY AND MARTIN’S

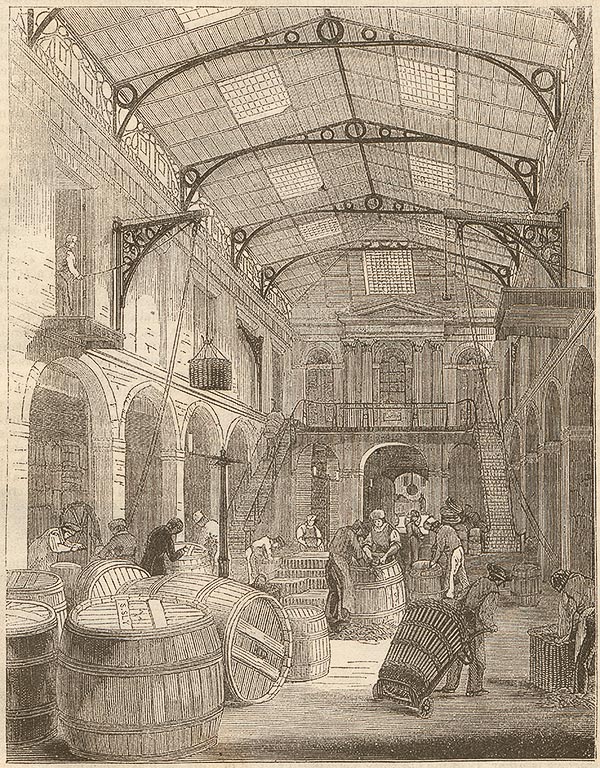

Packing-Warehouse – Day and Martin\’s blacking factory

GAY, the author of the well-known ‘Fables, published, somewhat above a century ago, a lively work under the title of ‘ Trivia, or the Art of Walking the Streets of London ;’ in which he thus addresses the “shoe blacks,” an important fraternity at that time:-

“Go, thrive : at some frequented corner stand;

This brush I give thee, grasp it in thy hand;

Temper the foot within this vase of oil,

And let the little tripod aid thy toil;

On this methinks I see the walking crew,

At thy request, support the miry shoe;

The foot grows black that was with dirt embrown’d,

And in thy pocket jingling halfpence sound.

The Goddess* plunges swift beneath the flood,

And dashes all around her showers of mud:

The youth straight chose his post ; the labour ply’d

Where branching streets from Charing Cross divide

His treble voice resounds along the Mews,

And Whitehall echoes – ‘Clean your Honour’s Shoes.'”

* Gay gives to the shoe-black a mythological descent from the Goddess of Mud.

One of the early numbers of Mr. Knight’s ‘London,’ wherein the above lines are cited, thus records a modern revolution in the black-ball world:- “In one of the many courts on the north side of Fleet Street, might be seen, somewhere about the year 1820, the last of the shoe-blacks. One would think that he deemed himself dedicated to his profession by Nature, for he was a negro. At the earliest dawn he crept forth from his neighbouring lodging, and planted his tripod on the quiet pavement, where he patiently stood till noon was past. He was a short, large-headed son of Africa, subject, as it would appear, to considerable variations of spirits, alternating between depression and excitement, as the gains of the day presented to him the chance of having a few pence to recreate himself, beyond what he should carry home to his wife and children. For he had a wife and children, this last representative of a falling trade; and two or three little woolly-headed decrotteurs nestled around him when he was idle, or assisted in taking off the roughest of the dirt when he had more than one client. He watched, ·with a melancholy eye, the gradual improvement of the streets; for during some twenty or thirty years he had beheld all the world combining to ruin him. He saw the foot-pavements widening; the large flag-stones carefully laid down; the loose and broken piece, which discharged a slushy shower on the unwary foot, instantly removed: he saw the kennels diligently cleansed, and the drains widened: he saw experiment upon experiment made in the repair of the carriage-way, and the holes, which were to him as the ‘old familiar faces’ which he loved, filled up with a haste that appeared quite unnecessary, if not insulting.”

We may picture to ourselves an old gentleman of the last century, with his foot upon a stool, reaping the lustrous fruits of the shoe-black’s labours; and we may fancy we hear him cry – “Clean your Honour’s Shoes!” But (to quote from the same work) “The cry is no more heard. The pavements of Whitehall are more evenly laid than the ancient marble courts of York Place, where Wolsey held his state, and Henry revelled; and they are far cleaner, even in the most inauspicious weather, than the old floor beneath the rushes. Broad as the footways are, as the broadest of the entire original streets, the mightiest of paving-stones is not large enough for the comforts of the walker; and a pavement without a joint is sought for in the new concrete of asphaltum. Where the streets which run off from the great thoroughfares are narrow, the trottoir is widened at the expense of the carriage-road; and one cart only can pass at a time, so that we walk fearless of wheels. If we would cross a road, there is a public servant, ever assiduous, because the measure of his usefulness is that of his reward, who removes every particle of dirt from before our steps. No filth encumbers the kennels; no spout discharges the shower in a torrent from the house-top. We pass quietly onwards from the Horse Guards to the India House without being jostled off the curb-stone, though we have no protecting posts to sustain us; and we perceive why the last of the shoe-blacks vanished from our view about the time when we first noticed his active brothers at every corner of Paris – a city then somewhat more filthy than the London of the days of Anne.” *

We may picture to ourselves an old gentleman of the last century, with his foot upon a stool, reaping the lustrous fruits of the shoe-black’s labours; and we may fancy we hear him cry – “Clean your Honour’s Shoes!” But (to quote from the same work) “The cry is no more heard. The pavements of Whitehall are more evenly laid than the ancient marble courts of York Place, where Wolsey held his state, and Henry revelled; and they are far cleaner, even in the most inauspicious weather, than the old floor beneath the rushes. Broad as the footways are, as the broadest of the entire original streets, the mightiest of paving-stones is not large enough for the comforts of the walker; and a pavement without a joint is sought for in the new concrete of asphaltum. Where the streets which run off from the great thoroughfares are narrow, the trottoir is widened at the expense of the carriage-road; and one cart only can pass at a time, so that we walk fearless of wheels. If we would cross a road, there is a public servant, ever assiduous, because the measure of his usefulness is that of his reward, who removes every particle of dirt from before our steps. No filth encumbers the kennels; no spout discharges the shower in a torrent from the house-top. We pass quietly onwards from the Horse Guards to the India House without being jostled off the curb-stone, though we have no protecting posts to sustain us; and we perceive why the last of the shoe-blacks vanished from our view about the time when we first noticed his active brothers at every corner of Paris – a city then somewhat more filthy than the London of the days of Anne.” *

* London, chap. ii., ‘Clean your Honour’s Shoes,’ p. 18.

But if this be so – if the streets be so ‘incomparably cleaner now than they were a century ago (and no one can doubt it), what must become of the blacking-makers? The shoe-blacks of old became street-sweepers by degrees, from utter want of custom; and it might be feared that the vendors of the “incomparable jet” – the “easy-shining” composition which produces “the most brilliant lustre ever beheld,” and will “keep good in any climate” – would likewise be driven to seek another source of employment. By no means. The blacking-makers are more important personages now than ever they were; they surprise us with magnificent buildings – more like mansions than factories – and with horses and waggons, travellers and agents, and all the commercial machinery incident to a large branch of manufacture. What sort of blacking the Londoners used a century ago, or who were the persons by whom it was made, we do not know; but if the streets are less miry than they were then, and yet blacking be more generally used by all classes, we arrive at a sort of logical deduction, that we are a more cleanly people than our ancestors – that the boots and shoes of 1842 are more resplendent than those of 1742. A city clerk or a London tradesman, instead of applying to the shoe-black at the corner of a court, and staying there until “the foot grows black that was with dirt embrown’d,” now has the mirror-like polish imparted to his boots before he leaves his home: he does not leave his door in search of an agent of cleanliness, for every house has now such an agent within.

We are not about to instruct the reader how to make a bottle of blacking; but we hope to convey a slight idea of the large and remarkable extent of the arrangements involved in the manufacture, as carried on by a celebrated London firm. If anyone were to picture to himself a dark and dirty room, containing a few tubs and coppers, and half a dozen men mixing up and bottling a black liquid – their faces and garments vying with the tubs and floor in blackness (and such a picture is not unlikely to be formed), he would be somewhat surprised at witnessing, as we have recently done, the scene presented at “Day and Martin’s” factory in Holborn. Whether we regard this establishment in respect to its elegant exterior, the large and lofty packing-warehouse which forms its main apartment, the ranks and files and tiers of bottles in the ‘filling rooms,’ or the general economy which pervades the manufacture of a commodity apparently so humble as backing, there is much to admire, and, perhaps we might say, much more from which instruction might be reaped; for the division of labour, and the apportionment of duty, so that every man may be ready to do the work at the moment when the work is ready for him, and have just as much to do as will occupy his whole working-day, are features of factory-economy in which much ingenuity and calculation are called for.

All the world has heard of “Day and Martin” The two names are so associated that we can hardly conceive a Day without a Martin, or a Martin without a Day; and that either Day or Martin should ever die, or be succeeded by others, seems a kind of commercial impossibility – a thing not to be thought of. “Day and Martin” it has been for forty years, and “Day and Martin” it will probably be for forty years to come, or perhaps till blacking itself shall be no more. To “Day and Martin’s,” then, the reader’s attention is directed.

Those who knew High Holborn a dozen years ago may perhaps remember the former premises occupied by this firm: unimportant and inelegant, they called for no admiration without, and probably possessed little symmetry of arrangement within. Since then, however, the whole of the premises have been built on a scale of great magnificence. On the north side of Holborn, between Red Lion Street and Kingsgate Street, a frontage of about ninety feet shows the façade of the new building. As all the manufacture is carried on in the rear of the premises, the front buildings are leased off to other parties, with the exception of the central portion, which pertains to the factory. From the arched entrance, the premises extend to a distance of upwards of two hundred feet northward, to a street running parallel with Holborn; and the working parts of the factory are nearly a hundred feet in width. The site on which the factory stands affords an instructive example of the value imparted by manufacturing premises to the land on which they are situated. This site, and a considerable portion of ground near it, was purchased many years ago, by the parish authorities of St. Clement Danes, for a sum of one hundred pounds, which was put into the poor-box by some benevolent person. The rack-rent of this same portion of ground now amounts to four thousand pounds per annum, and will probably go on increasing in value!

On entering from Holborn, we come first to a range of offices and counting-houses, lying on the right hand side of the main archway or entrance. The polished mahogany desks and cases of these offices are the scene of book-keeping operations of the customary kind, and do not call for notice here. At the north end, the wide entrance passage terminates in a large arched window, between twenty and thirty feet in height, a door in the lower part of which leads to the ‘warehouse,’ the central portion of the whole establishment. This warehouse has a striking effect, both from its wide and lofty dimensions, and from the busy operations of which it is the theatre. Its area is perhaps not much less than a hundred feet square; and its general arrangement will be better understood if we divide it into three portions, a centre and two sides, running parallel from north to south. The central portion is open from the ground to the iron roof, a height of probably fifty feet. It is lighted by about a dozen sky lights in the roof, and by an ornamental kind of window, or glazed scroll-work, extending along both sides between the walls and the roof. This central area is separated from the side aisles (if we may so term them) by arches and piers of brickwork, beyond which are these side warehouses, lighted only from the central skylight and windows.

The northern end of the warehouse presents, in the lower part, an arched entrance to another warehouse or store-room beyond, and at the upper part, doors and windows belonging to the ‘tun-room,’ or manufactory in which the blacking is made. Two light and elegant iron staircases lead from the floor of the warehouse to the level of this upper room, one on each side. The side warehouses or aisles are not above half the height of the central portion; for they have over them two very long rooms or galleries called ‘filling-rooms.’ Four openings furnish communication between these filling-rooms and the warehouse, two on each side; that is, one opening to each, in communication with the iron staircase, and one by which crates are hauled up to, or lowered from, the filling-room. If the side of each filling-room were thrown open, the whole would bear some resemblance to the form of a church; there would be a nave, or middle aisle, two side aisles, and two galleries over the latter.

This warehouse, from morning till night, is a continued scene of bustle and activity. It is the part of the premises in which the finished commodity is packed for London shopkeepers, for country trade, or for foreign shipment. Packers and porters and coopers occupy the greater part of the central area. The coopers are making or altering and adjusting the casks in which the bottles are generally packed; for many of the casks are made here from the rough staves, and all are fitted to the wants of the packers. The packers are in all sorts of attitudes, according to the state of the cask which is being filled: some are bending over the cask, to put in the lower layer of bottles; some, by having nearly filled a cask, are enabled to stand either more erect at their work; one man has got his foot in a cask, pressing down the straw; another, with a stick in his hand, is thrusting straw between the bottles; some are closing in the casks; and the porters are arranging the filled casks ready for removal from the factory. At night, both the filling-rooms and the warehouse are lighted with gas, by branches ranged along the centre.

The side warehouses, or those portions which are separated from the centre by the arches and piers, are crammed with enormous piles of stores, pertaining to some branch or other of the manufacture. Casks ranged by scores and by hundreds; staves and hoops for the use of the coopers; crates of empty stone bottles; huge bags of corks or bungs, containing a hundred gross or more in each bag; boxes for packing ‘paste-blacking,’ -these are some of the multitudinous stores here deposited. An underground furnace and boiler, under each of the galleries, furnish hot water for heating the whole premises; and subterraneous communication is kept open from one side of the building to the other. Under the right hand gallery is deposited a kind of fire-escape, consisting of a series of ladders capable of sliding, telescope-like, to a height of a hundred feet; by which any part of the walls or roof may be reached from below, either for cleaning or repairing, or any more urgent purpose. Near the south-eastern corner of the warehouse are several rooms devoted to the labels, papers, and wrappers, to which we shall allude further by and by; and over some of these rooms is a very large reservoir, from which an abundant supply of water can be obtained in case of emergency.

Before ascending the two dozen steps which lead up to the galleries, we will follow out the lower range to its northern termination. An archway leads from the large warehouse to a smaller store-room filled with stores like the other. The western exhibits rows and piles of casks heaped up to the ceiling; while crates are here and there deposited, containing bottles afterwards to be filled, each crate holding about a hundred dozens. At the eastern side of this store-room is a kind of washing-house, where old and used bottles are cleansed before being employed again. Everyone who is learned in the matter of domestic perquisites knows that old blacking-bottles, like old things of many other kinds, can find a market: the manufacturer would probably be quite as well pleased to use new bottles altogether, and save himself the trouble of washing old ones; but whenever this washing is necessary, it is effected in the washing-house. Coppers, and tubs, and brushes, sloppiness below, and steam above, all indicate the somewhat dirty occupation of bottle-washing; while near at hand are the crates into which the cleansed bottles are put.

In this part of the factory is also a furnace and the necessary apparatus for preparing the red-wax with which the corks of blacking-bottles are sealed. Those who know anything of the nature of sealing wax, whether the finer kinds for sealing letters, or the courser kinds for sealing bottles, need hardly be told that ‘wax’ is altogether a misnomer, for there is no wax in it. It is a compound of several resinous substances, coloured by some one among the numerous mineral colours. In the finer qualities, gum-lac is the principal resin, spirit of wine the principal solvent, and vermilion the chief colouring substance. Among manufacturers, however, common resin and spirits of turpentine and Venetian red, or some analogous materials, are sufficiently good for the materials of ‘bottle-wax.’ In this part of the factory bags and boxes and tubs of the ingredients are disposed conveniently for the manufacture, and a particular kind of furnace is provided for melting them. This furnace is deeply imbedded in brickwork, and situated in a recess quite secluded from any other part: it has also a very heavy iron shutter which can be drawn down in front of it in an instant, and thus render the occurrence of an accident from fire scarcely possible. The melted ingredients, when thoroughly mixed, are poured into vessels to cool, thence to be removed and re-melted in a way of which we shall speak hereafter.

Proceeding still farther northward, we come to a pair of folding-gates, which open into the last portion of this range. We here find the cart and waggon house, where the carts and wagons are kept which convey the manufactured article to the London dealers, the coach, waggon, canal, and railway offices, and the docks and shipping wharfs. On each side are stables for the horses, over which are corn and hay lofts.

This brings us to the extremity of the range, to which an entrance is obtained by folding-gates from a small street beyond.

Let us now return to the great warehouse, and ascend one of the iron staircases to the upper range of buildings. Having surmounted this stair and reached a platform which crosses the northern end of the warehouse at a height of above twenty feet from the ground, we obtain a bird’s-eye view of the operations below; and a busy scene it is. The coopers and packers are distributed about the whole area below; crates of empty bottles are being hauled up, and other crates of filled bottles are being lowered. Opposite, at the southern end, a large clock meets the eye; and through the large arched window we catch a glimpse of bustling Holborn.

Passing from this platform or passage into one of the galleries, or ‘filling-rooms,’ we find doors leading into the northern range of upper rooms, comprising those in which the manufacture is principally conducted. One of these, used as a store-room, opens upon the street behind, from which tubs, and butts, and casks of ingredients are hauled up and stowed round the room. The vinegar comes in casks of sixty gallons each, the oil in larger casks, the ‘ivory-black’ or other kinds of black in casks containing nearly a ton each, and the remaining ingredients in packages and casks of various kinds, according to their quality.

From the store-room the ingredients are brought into the ‘tun-room,’ or manufactory, the least attractive but the most important place in the establishment. It is singularly occupied. Nearly a hundred tubs, each capable of containing about a hundred gallons, are ranged from end to end of the room in regular rows. Each tub is supported on a separate stand, or trestle, half a yard in height; and each one is capable of being moved by a couple of men at a certain stage in the manufacture. The tubs are all more or less filled with blacking, according to the hour of the day when they are seen. A few of them are filled with blacking of a stiffer or thicker consistence. The room also contains other vessels and apparatus connected with the manufacture.

On either side of this room are smaller rooms, in which subsidiary portions of the manufacture are carried on. In one are the vessels and arrangements for filling pots and tin cases with paste-blacking; and round this room are stored in immense number cylindrical packets, each containing a dozen tin-boxes, intended for the use of the army. A soldier is not provided with any too much room for his implements and appurtenances, and a bottle of liquid-blacking would be rather a burden to him. Yet, as the soldier’s boots or shoes must to some extent emulate the brightness and glitter of the boots of those who pay for battles instead of fighting them, a portable blacking apparatus is provided. The blacking, instead of being liquid, is made into stiff paste, and in that state is put into circular tin-boxes, about three inches in diameter, and half or three-quarters of an inch thick. What becomes of the tin-boxes when emptied – whether they are applied to any useful purpose, or whether, like the millions of pins made every year, they go no one knows whither – we cannot say.

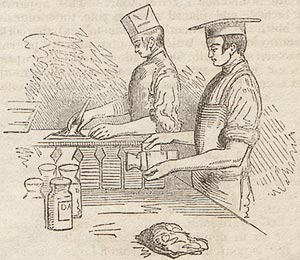

From this room we proceed to the western gallery, or ‘filling-room,’ a room in which bottles certainly have the ascendant; for what with hauling up and opening crates, and disposing bottles on benches, and filling, and corking, and sealing, and labelling, and storing on shelves, it is certainly the busiest ‘bottle department’ we have seen. The arrangement of this room is well adapted to facilitate the rapid progress of the manufacture. It is about ninety feet in length, and perhaps one-third as broad. Along the middle extends a double row of shelves or stands, three or four in height, each shelf being calculated to hold bottles. Along the eastern and western walls are similar tiers of shelves or stands adapted for similar purposes. In the two avenues which separate these series of shelves are broad benches, fitted for holding the bottles during the processes of filling, corking, sealing, pasting, &c. At about the middle of its length is a door or opening in the east side, which places the filling-room in communication with the warehouse below. A crane is fixed immediately outside this opening, by which crates of empty bottles are drawn up from the warehouse, and baskets of filled bottles lowered from the filling-room. The tiers of shelves in the room are fixtures; but the benches are provided with castors or wheels, by which they may be moved from place to place, according as convenience may require. The room is lighted by ten or a dozen sky lights in the daytime, and by gas at night, or rather in the evening. According to the time of the day when the filling-room is visited, will be the nature of the operations witnessed; but at all hours, from an early time in the morning till eight in the evening, men and boys are actively engaged in the operations which intervene between the making and the packing of the ingredient.

The western filling-room communicates with two of the manufacturing rooms and also with the iron platform stretching across the northern end of the warehouse. We will therefore pass along this platform and visit the eastern filling-room, which resembles the other in its main features. There are ranges of shelves for bottles, disposed one above another, and in parallel ranges; but the eastern half of the room is somewhat differently occupied. Here the shelves, instead of being occupied by bottles, contain trays filled with blacking of a different kind, placed there to cool and solidify. The benches, too, and the operations of the workmen, are adapted to the preparation of paste-blacking rather than that of a liquid kind. All the shelves in the two filling-houses are capable of containing six or seven thousand dozens of bottles; and as these bottles seldom remain many days on the shelves before they are packed, an incessant interchange is going on – from the manufactory to the filling-room, from thence to the warehouse, and from thence to the purchaser. The odour of the filling-rooms, as well as of those more immediately pertaining to the manufacture gives to the visitor unmistakable evidence that vinegar is one, and a principle one, of the ingredients employed.

We have now made a tour of the rooms of this remarkable establishment, and may next endeavour to give a slight outline of the modes of proceeding in the course of the manufacture. There is, to be sure, nothing very elaborate, no complicated machinery, no array of engines and machines for making the commodity produced; but still there are some manipulations which strike a stranger as being not a little curious, illustrating as they do the dexterity which is acquired by long practice in some one particular department of labour. This dexterity of hand (which, by the way, is exactly expressed by the French word “legerdemain,” although we usually attach a conjuring meaning to this term) is most frequently exhibited in branches of manufacture where machinery has not been extensively introduced, and is often more interesting to a looker-on than the complicated action of an elaborate machine.

There are many ingredients employed in the making of blacking, each manufacturer having a recipe of his own. If therefore, the reader should look out for an exposition of the whole affair, the names and proportions of the ingredients, the temperature of mixture, and so on, we shall not be able to furnish these details; for – to use an expression which Scott puts into the mouth of one of his characters, in relation to a very different subject – “we cannot, if we would; and we ought not, if we could.” Let it suffice for our present object to know that ivory-black or some similar substance constitutes the principal colouring-material, and that vinegar and oil are the two principal liquids.

At five o’clock in the morning, winter and summer, the manufacture of each day’s quantum of blacking commences. The work is not extended from day to day, one portion of the manufacturing processes being effected on one day and the remainder on another; but each day’s labours are complete in themselves, so that a ‘day’ at a blacking-factory is a tolerably uniform day. The ‘tun-room’ or that part of this establishment which is called the ‘manufactory,’ is the scene of operations in the first instance. The mixing-vessels are ranged in rank and file over the greater portion of the room. A stirring or mixing apparatus is ingeniously contrived so as to be applicable to all the vessels, one after another, and is worked through the medium of a shaft descending to a room below, where the moving power is applied. The oil, the black, the vinegar, and the other ingredients are brought from the adjacent store-room, and are mixed and worked up in the requisite proportions; the temperature, the stirring, and the general order of processes being of course dependent on the system of manufacture which the firm pursues.

While the manufacture of the commodity is being thus carried on in the northern part of the premises, the other workmen, in the ‘filling-rooms’ and warehouse, are preparing for the bottling arrangements. The bottles employed, as most persons are probably aware, are made of brown glazed earthenware: they have very wide mouths, and are made of three different sizes, calculated to hold a pint, two-thirds of a pint, and one-third of a pint each. They are principally made at the Derbyshire potteries, and are brought to London packed with straw in large crates, each crate containing on an average about a hundred dozen bottles, and weighing half a ton. The crates are first deposited on the floor of the warehouse, and are thence hoisted up to the filling-rooms by means of the large cranes seen In our frontispiece. When a crate is deposited In the filling-room, it is at once opened, and the bottles passed on with great quickness from hand to hand, and laid in regular rows on the broad benches near the centre of the room.

When the bottles are all thus arranged, and the blacking is in a prepared state, the latter is brought out of the tun-room or manufactory by several men, each tub or vessel being brought on the stand or frame by which it is supported. These vessels, to a considerable number, are then placed at equal distances near the bench which contains the empty bottles; and the process of filling then begins. Each vessel is attended by a man and a boy, the latter of whom continually stirs the blacking till the whole of it is bottled. The man stands by the side of the vessel with his left hand next to the bench of empty bottles; and in his right hand he holds a measure, or small can. Taking up a bottle in his left hand, he fills it with blacking by means of his measure; the size of the measure, and the quantity of blacking which he collects in it at each dipping into the vessel, being so adjusted to the size of the bottles as to expedite the process as much as possible. The laying-down of the filled bottle and the taking up of an empty one are but the work of a moment; every little circumstance being pre-arranged which could in any way facilitate it.

When the bottles are all thus arranged, and the blacking is in a prepared state, the latter is brought out of the tun-room or manufactory by several men, each tub or vessel being brought on the stand or frame by which it is supported. These vessels, to a considerable number, are then placed at equal distances near the bench which contains the empty bottles; and the process of filling then begins. Each vessel is attended by a man and a boy, the latter of whom continually stirs the blacking till the whole of it is bottled. The man stands by the side of the vessel with his left hand next to the bench of empty bottles; and in his right hand he holds a measure, or small can. Taking up a bottle in his left hand, he fills it with blacking by means of his measure; the size of the measure, and the quantity of blacking which he collects in it at each dipping into the vessel, being so adjusted to the size of the bottles as to expedite the process as much as possible. The laying-down of the filled bottle and the taking up of an empty one are but the work of a moment; every little circumstance being pre-arranged which could in any way facilitate it.

It might at first thought be supposed that this process would be effected more quickly if the liquid were drawn out of a large vessel at once into the bottles by means of a cock or valve. But there are doubtless good reasons for adopting the opposite course. It may be that a sediment would fall to the bottom of the vessel, or that the liquid would flow from the cock too rapidly to enable the filling of each bottle to be adjusted to the required point; for the quantity poured into each bottle is very exact. But be this as it may, the filling is effected by hand; several open vessels being ranged along the filling-room, and each one being attended by a man and a boy, whom we may perhaps term a ‘filler’ and a ‘stirrer’.

The corking of the bottles is the next process. We have said that, in the warehouse beneath, the corks are stored in bags or sacks containing a hundred gross (fourteen or fifteen thousand) each. These bags are opened, and the corks are sorted into different parcels, according to the sizes of the bottles for which they may be adapted. They are then conveyed to the ‘filling-rooms,’ and the process of corking commences. A man, provided with an ample supply of corks, proceeds along the range of benches on which the filled bottles are placed, putting a cork into the mouth of each bottle, but without staying to fix or drive it in. Another man, provided with a wooden mallet, immediately follows him, and forces the corks so far into the bottles, that the upper surface of each shall be level with the top of the bottle, a succession of smart blows being given to one cork after another. All this progresses with very great quickness, the bottle being ranged with such regularity as to afford every facility for the operation. Of the thousands of bottles which are filled every day, all are corked in this way, by a sufficient number of men, each pair taking one bench or range of benches.

The bottles are filled, and the corks are adjusted in their places; but sufficient has not yet been done to secure the blacking in its ‘prison-house’. When a cork is so large as those here employed, the escape of the liquid contained in the bottle can scarcely be avoided unless some cement covers the whole surface of the cork and mouth of the bottle. A coarse kind of sealing wax, as we have before observed, is used for this purpose, and is of course applied in a melted state. In some of the upper rooms of the factory are several portable stoves for melting the wax. These consist of tripods, supporting a brazier or pan for containing ignited charcoal; and immediately above the brazier is a kind of bowl or ladle for containing the sealing wax. This substance, after being prepared, as was before alluded to, in the lower part of the factory, is taken up in lumps, an melted in these bowls or ladles. When melted, it has a cream like consistency, and presents the well known red colour. This apparatus being ready, and placed close beside the ranges of filled bottles, a workman proceeds to seal the corks. He has no brush, no ladle, no contrivance for pouring the wax on the cork, but, holding the bottle upside down, he just immerses the corked surface in the liquid wax. Practice has enabled the men to effect the dipping so exactly, that the wax rarely comes over the sides of the bottle. The apparently simple matter of reversing the bottle again, without scattering the wax, or causing it to flow over the sides of the bottle, is effected by a peculiar movement of the wrist and hand, impossible to describe and difficult to imitate. Many of our manufactures present analogous instances, in which a process is effected quite as much by the muscular movement of the hand as a whole, as by the delicate agency of the fingers. For instance, ‘imitation’ or ‘mock pearls’ are made by blowing glass beads so that each bead shall be hollow and shall have two holes in the exterior; then a liquid, made of a pearl-like powder obtained from the scales of fish, is dexterously blown into the hollow of the bead through a tube; and by a peculiar twisting of the hand, this single drop of liquid is made to diffuse itself over the internal surface of the bead, without having more or less than just enough to cover the whole. Again, in type-founding, when the melted type-metal has been forced into the mould, the caster throws up his left hand with a peculiar motion, giving it a kind of jerk at the same time with his right, by which the liquid metal is forced or shaken into all the minute interstices of the mould. Instances of this kind might be adduced in great number; and among them is this one of sealing the filled bottles. The celerity, too, with which this is effected is not less note-worthy than the neatness; for a man can seal one hundred dozens of bottles in an hour, or twenty in a minute.

The bottles are filled, and the corks are adjusted in their places; but sufficient has not yet been done to secure the blacking in its ‘prison-house’. When a cork is so large as those here employed, the escape of the liquid contained in the bottle can scarcely be avoided unless some cement covers the whole surface of the cork and mouth of the bottle. A coarse kind of sealing wax, as we have before observed, is used for this purpose, and is of course applied in a melted state. In some of the upper rooms of the factory are several portable stoves for melting the wax. These consist of tripods, supporting a brazier or pan for containing ignited charcoal; and immediately above the brazier is a kind of bowl or ladle for containing the sealing wax. This substance, after being prepared, as was before alluded to, in the lower part of the factory, is taken up in lumps, an melted in these bowls or ladles. When melted, it has a cream like consistency, and presents the well known red colour. This apparatus being ready, and placed close beside the ranges of filled bottles, a workman proceeds to seal the corks. He has no brush, no ladle, no contrivance for pouring the wax on the cork, but, holding the bottle upside down, he just immerses the corked surface in the liquid wax. Practice has enabled the men to effect the dipping so exactly, that the wax rarely comes over the sides of the bottle. The apparently simple matter of reversing the bottle again, without scattering the wax, or causing it to flow over the sides of the bottle, is effected by a peculiar movement of the wrist and hand, impossible to describe and difficult to imitate. Many of our manufactures present analogous instances, in which a process is effected quite as much by the muscular movement of the hand as a whole, as by the delicate agency of the fingers. For instance, ‘imitation’ or ‘mock pearls’ are made by blowing glass beads so that each bead shall be hollow and shall have two holes in the exterior; then a liquid, made of a pearl-like powder obtained from the scales of fish, is dexterously blown into the hollow of the bead through a tube; and by a peculiar twisting of the hand, this single drop of liquid is made to diffuse itself over the internal surface of the bead, without having more or less than just enough to cover the whole. Again, in type-founding, when the melted type-metal has been forced into the mould, the caster throws up his left hand with a peculiar motion, giving it a kind of jerk at the same time with his right, by which the liquid metal is forced or shaken into all the minute interstices of the mould. Instances of this kind might be adduced in great number; and among them is this one of sealing the filled bottles. The celerity, too, with which this is effected is not less note-worthy than the neatness; for a man can seal one hundred dozens of bottles in an hour, or twenty in a minute.

The sealing, as well as the filling and corking, is effected in the two ‘filling-room’; and so is likewise the next process, which is perhaps the most remarkable to a stranger of all which the factory presents, from the astonishing rapidity with which it is effected, – we allude to the pasting of the labels on the bottles. But before speaking of this process, it will be desirable to pay a little attention to the labels themselves, the complexity of which has doubtless puzzled many persons.

Those who have not watched the proceedings of the last few years in respect of colour-printing, can perhaps scarcely conceive how the printing of these blacking labels can be effected. If we examine one of “Day and Martin’s” labels, we see that nearly the whole of the ground consists of a kind of lace-work, red on white paper, the meshes or interstices being probably about one-twentieth of an inch in diameter. This ground-work, occupying about sixteen square inches, is diversified by several compartments printed in black ink; one, for instance, containing a view of the front façade of the factory; another, the name of the firm; a third, the retail price of the commodity contained in the bottle; a fourth; the number of the house, curiously bedecked with a double enunciation of the name of the firm; and two others containing remarks and directions to the purchaser. All these are printed with black ink on the white paper, no red lace-work being here seen. Above these are letters printed in black and white on a wavy or undulating ground of black, red, and white; while at the top are black letters, and at the bottom letters in white, red, and black, printed on, or at least interspersed among, the lace-work ground itself. All this relates to the labels for the liquid blacking contained in bottles; and the circular labels for paste blacking are on the same principle, though different in detail.

Now it may naturally be asked by those to whom the subject is new, how these various devices, and these differently coloured inks, can be imprinted on one piece of paper without confusion or distortion. Without going into any description of the various modes by which printing in diverse colours is now effected, we will attempt a brief sketch of the contrivance by which these labels are produced. One of the rooms in the factory is a printing-room, in which is contained a beautiful machine, invented by Mr. E. Cowper, of King’s College, who was the original patentee of the machine by which this Magazine is printed. It is a cylinder printing-machine, specially adapted for printing many-coloured devices, such as those on these labels. There is one cylinder for printing all the red portion, and another for printing the black. Eight labels are printed at once, but it will simplify the description if we speak only of one. In the first place a stereotype plate is arranged for receiving the device of the black portion of the label; and another, exactly the same size, for the red portion. These plates, for the liquid blacking, measure rather less than five inches by four; and on the surface is depicted, in relief, all the letters and ornaments, which are afterwards inked and printed; the plates being prepared, we believe, by a combined process of casting, stamping, and modelling. The plates are so exactly adjusted, that every raised part in one of them shall coincide with a depressed part in the other, and vice versa. This is in fact precisely the same principle as that on which the several blocks for printing floor-cloths are adjusted, as described in one of our recent Supplements. The nature of the adjustment might be instructively shown by printing a label by hand with the two plates; although, of course, this would never do in practice. We might take one of the plates, carefully ink its surface either by an inking-ball or an inking roller, and then impress it on a piece of damp paper. Then (supposing the first inking to have been black) if we ink the second plate with red, and print the paper a second time, the clearness or confusion of the resulting device would correctly measure the degree of accuracy with which the one impression was superposed on the other. It would be seen how very small a deviation from exactness in the adjustment of the second plate would be sufficient to give a distorted appearance to the label.

If the printing-machine were adapted for flat printing, these prepared plates might be adjusted to a flat bed or support. But a cylinder-machine is employed, in which both the plates lie on the surface of cylinders. Here, however, a difficulty at once occurs. If flat plate be placed on a curved surface, it is easy to see that they cannot conform to the curvature of that surface; and the mode of contact between the plates and a sheet of paper to be printed would be wholly incompatible with the object in view. The means had therefore to be devised of curving the plates without disturbing the device on their surfaces; and this has been effected. Eight plates, all exactly alike, are bent in conformity with the curvature of the cylinders, and are then fixed to the surface of one of the cylinders by means of delicate adjusting mechanism. Eight other plates, all alike, but differing from the former, are similarly fitted to the surface of the other cylinder. These two cylinders are so adjusted in the machine as to rotate in contact, or nearly in contact, with a third, round which a sheet of paper may be made to travel. An inking apparatus for black ink is placed near one cylinder at one end of the machine; another apparatus for red ink is fixed near the other cylinder at the other end; and when the machine is at work, if a sheet of damp paper be placed at one end, it is drawn into the machine, carried over and under various rollers, and made to pass under the two cylinders. Meanwhile, by various rollers and other connecting mechanism, the eight plates on the one cylinder become coated or charged on the projecting parts with black ink, and those on the other with red; and matters are so adjusted, that exactly when the paper comes near the black-inked cylinder, the plates are ready to print; and immediately after the paper has received its black impress, it is caught by the other cylinder and printed with the red portion of the device. As may be readily supposed, the most scrupulous exactness of adjustment is necessary, in order to ensure the juxtaposition of the red and black portion of the device at the proper places. By means of adjusting-screws, the printing-plates can be shifted to so minute a distance as the two-hundredth of an inch, in order to bring the ‘register,’ or superposition of device, at the proper points. One grain of ink only is used to print eight labels. The circular labels for the paste-blacking tin boxes, as well as the square ones for the bottles, are printed at this press. The demand is so large and so constant, that the machine is nearly always at work; and when the sheets of labels are printed, boys are employed to cut the separate labels from them.

These are the labels, then, which we are now to see pasted on the bottles. One man or boy can paste as many labels as two others can attach to the bottles, so that they work together in groups of three. On the bench is placed on the one side a large tub of paste, and on the other a ranged series of filled and sealed bottles. A heap of labels is laid down face downwards, and the paster pastes them one by one with a brush. The dexterity in this simple act is not in the pasting, but in a peculiar final touch with the brush, by which the pasted label is jerked off the heap, and caught in the left hand. So rapidly is this effected, that one man will paste a label, jerk it off the heap, catch it in his left hand, and lay it on one side, nearly two thousand times in an hour; for one man can thus paste a hundred and sixty dozen labels in this time. As fast as the labels are pasted, the other two workmen attach them to the bottles. Each one takes a bottle in his left hand, and a pasted label in his right, and attaches the one to the other by two or three touches which the eye can scarcely follow. To a spectator it seems that almost before the bottle is taken fairly into the hand, it is laid down again, properly labelled. Let any uninitiated person endeavour thus to secure sixteen labels per minute to as many bottles, and see what progress he will make.

The labelling of the bottles is the last process which is effected in the filling-room. All the bottles, after having been labelled, are ranged on the systems of shelves in the filling-rooms, and there kept till the paste is properly hardened. They are then put into a basket, and lowered from the filling-room to the warehouse by the aid of one of the cranes. Here they pass into the hands of the packers and coopers. The general mode of sending out the bottles from the factory is in casks, containing from three to a hundred dozens. The casks are prepared by the coopers to the proper dimensions, and the packers proceed with their work. This like many other apparently simple operations require tact and judgement. The packer first ranges a circle of bottles around the inner surface of the cask, then encircles a wisp of straw within this ring of bottles, and then arranges a smaller ring. In this way he proceeds till one tier is filled; and by the aid of a stick or wedge he inserts straw and extra bottles wherever there is room for one or another, until at length the whole are jammed immoveably together. A second tier of bottles is then built up, separated from a lower one by a layer of straw; and this is in a similar manner hardened and compressed till nothing can shake about or become displaced. So on to the top of the cask, which is finally topped with straw, and the head fastened in, ready for marking and carting.

The labelling of the bottles is the last process which is effected in the filling-room. All the bottles, after having been labelled, are ranged on the systems of shelves in the filling-rooms, and there kept till the paste is properly hardened. They are then put into a basket, and lowered from the filling-room to the warehouse by the aid of one of the cranes. Here they pass into the hands of the packers and coopers. The general mode of sending out the bottles from the factory is in casks, containing from three to a hundred dozens. The casks are prepared by the coopers to the proper dimensions, and the packers proceed with their work. This like many other apparently simple operations require tact and judgement. The packer first ranges a circle of bottles around the inner surface of the cask, then encircles a wisp of straw within this ring of bottles, and then arranges a smaller ring. In this way he proceeds till one tier is filled; and by the aid of a stick or wedge he inserts straw and extra bottles wherever there is room for one or another, until at length the whole are jammed immoveably together. A second tier of bottles is then built up, separated from a lower one by a layer of straw; and this is in a similar manner hardened and compressed till nothing can shake about or become displaced. So on to the top of the cask, which is finally topped with straw, and the head fastened in, ready for marking and carting.

Such is the career of a bottle of blacking, before it leaves the hands of the manufacturer. But there are one or two other forms of blacking which we may briefly notice, in illustration of the arrangements of this factory.

We have before said that in one of the rooms of the factory small tin boxes are piled in great number, and that these contain, or are destined to contain, paste-blacking for the use of the army. Whether any particular ingredients are used in this composition, different from or in addition to those which compose liquid blacking, we do not know; but the consistence to which it is mixed is much stiffer. The paste-blacking, when fully prepared, is contained in a large vessel or tub, round which two or more boys place themselves, each one provided with a small scoop or ladle, shaped like a spoon, with the handle affixed to one side instead of one end. Tin boxes are close at hand, which the boys take one by one, and fill with the thick paste-like blacking. All the boxes, as they are filled, are ranged in rows in the filling-room, where they remain till the blacking has solidified, and assumed a stiff clayey consistence. Then, tin covers are put on them, and they are packed in dozens, and wrapped in paper. They reach the soldiers, we believe, through the medium of the army clothiers.

There is another kind of paste-blacking which is sold in little wide-mouthed stone pots, something like crucibles. This is nearly the same in quality as the soldiers’ blacking; while the pots are of the same character, as to material, as the bottles. The paste-blacking is laded into them by the same simple apparatus as into the tin boxes; and is then allowed to stand aside to solidify; after which the mouths of the pots are well secured with paper.

Another form of blacking, different from all the others, remains yet to be noticed. This is a kind which is stiffer than liquid or bottle blacking, but thinner than the other kinds: it is in fact a soft paste. Its mode of being packed into a saleable form, after the manufacture is finished, is very different from the other instances. Shallow moulds or trays are provided about half a yard long, two-thirds as wide, and half an inch or so in depth. Into these moulds the paste-blacking is poured or laded from a large vessel; and the moulds are then put by on shelves to cool and solidify. One side of the eastern filling-room contains a very large number of these moulds, standing by till their contained blacking has become cool. When this cooling is effected, each tray or mould is laid flat on a bench, and one of the edges or ledges is removed, so as to enable a knife to be passed under the solidified blacking, as a means of loosening it from the bed of the mould. The whole sheet of blacking, if we may so term it, is then cut up into six dozen rectangular pieces, twelve in length and six in width, by a convenient kind of knife; and the cakes are then in the shape in which they are sold. But they are too soft to be left without a covering; while, on the other hand, they require neither bottles, pots, nor tin boxes. Pieces of paper, first printed with the name of the manufacturer, &c., are well saturated with oil, and when dry, are fit to be used as wrappers to the small cakes of blacking. The papers are laid flat on a bench, one cake is put into each, and by one of those neat and expeditious manipulations which so many other parts the factory exhibit, the cakes are wrapped-up, each in its oiled paper. Then, in order to sell these cakes to the dealers in a form fit to be handled, small wooden boxes are provided, each capable of holding a certain number, packed neatly one upon another.

Another form of blacking, different from all the others, remains yet to be noticed. This is a kind which is stiffer than liquid or bottle blacking, but thinner than the other kinds: it is in fact a soft paste. Its mode of being packed into a saleable form, after the manufacture is finished, is very different from the other instances. Shallow moulds or trays are provided about half a yard long, two-thirds as wide, and half an inch or so in depth. Into these moulds the paste-blacking is poured or laded from a large vessel; and the moulds are then put by on shelves to cool and solidify. One side of the eastern filling-room contains a very large number of these moulds, standing by till their contained blacking has become cool. When this cooling is effected, each tray or mould is laid flat on a bench, and one of the edges or ledges is removed, so as to enable a knife to be passed under the solidified blacking, as a means of loosening it from the bed of the mould. The whole sheet of blacking, if we may so term it, is then cut up into six dozen rectangular pieces, twelve in length and six in width, by a convenient kind of knife; and the cakes are then in the shape in which they are sold. But they are too soft to be left without a covering; while, on the other hand, they require neither bottles, pots, nor tin boxes. Pieces of paper, first printed with the name of the manufacturer, &c., are well saturated with oil, and when dry, are fit to be used as wrappers to the small cakes of blacking. The papers are laid flat on a bench, one cake is put into each, and by one of those neat and expeditious manipulations which so many other parts the factory exhibit, the cakes are wrapped-up, each in its oiled paper. Then, in order to sell these cakes to the dealers in a form fit to be handled, small wooden boxes are provided, each capable of holding a certain number, packed neatly one upon another.

Thus have we rapidly sketched the chief manufacturing features of the place, so far as is necessary for the present object; and have to acknowledge the courtesy of the proprietors in furnishing the facilities for so doing. Every day, we have said, witnesses a pretty, regular and uniform series of operations. The actual manufacture takes place at an early hour in the morning; while the bottling, corking, sealing, labelling, moulding, and wrapping cake-blacking, bottle-washing, &c., occupy the remaining hours of the day in the upper and hinder rooms. The packing in the warehouse is so arranged as to enable the waggons and carts to be dispatched with one cargo to the various dealers, wharfs, docks, &c., in different parts of town, at a pretty early hour in the morning; and with another cargo at a later period of the day. Taken altogether, it must be owned that a day at “Day and Martin’s” is an early day, and a long day, and a busy day.

Printed by WILLIAM CLOWES and SONS, Stamford Street.